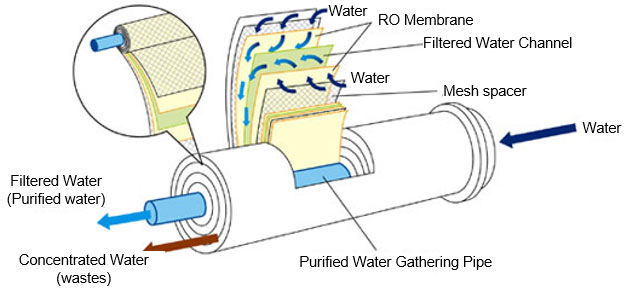

What is an RO (Reverse Osmosis) Membrane?

-“RO” stands for “Reverse Osmosis” and the RO Membrane is an advanced filter which can purify even sea water to be pure enough to drink*. The fibers of the

RO Membrane are so fine (1mm/10Mil) and it only let water molecule through.

That is why the RO Membrane can produce pure water from sea water.

Pros & Cons of RO Equipment

Pros

- Steady water production under any conditions – even in Stand-By mode/decelerated operation mode/rough weather conditions

- Minimizes frequency of shore fresh water supply

- Produces much more water without using waste heat, which makes the plant compact than evaporator types.

- Easier maintenance, lesser workload for crew with automatic operation

- More space for cargo, replacing with shore supplied water

- Reduces waiting time for shore supplied water

Cons

- Operation is limited at contaminated river (mud)/sea ports (same as evaporator)

- RO Membrane requires regular replacement (every 3-5 years)

- Chemical/filter requires regular replacement

- (When installing to existing vessels) Installing space is required in the engine room (carried out during Dry Dock)

Appearance/Specification

- Easy operation by following instructions on the touch panel

- Less time/complexity for component replacement

- Maintains high water quality by using a unique slime control chemical,which Kurita developed

- Minimizes your crew’s workload by operation/maintenance manuals that are easy to understand

| Type | |||

| Standard desalination capacity | |||

| Product quality | |||

| Water supply conditions | Std. water supply | ||

| Water quality | |||

| Water Temperature | |||

| Power supply | |||

| NRP of High-pressure pump | |||

| Size | Width | ||

| Length | |||

| Height | |||

| Product Weight | |||

| Full Equipped Weight | |||

Comparison(KURITA Serve Master vs Evaporator type)

|

|

|

| Type | RO Membrane | Evaporator |

| Heating System | Electric power | Waste heat from main engine+ electric power |

| Desalination Ratio | ±95% | ±70-80% |

| Fluctuation due to output from equipment | None | Yes |

| Operation | Auto(by button) | Manual(by valve) |

| Limitation | Contaminated river(mud)/sea ports | Contaminated river(mud)/sea ports/at Stand by mode |

| Maintenance | ||

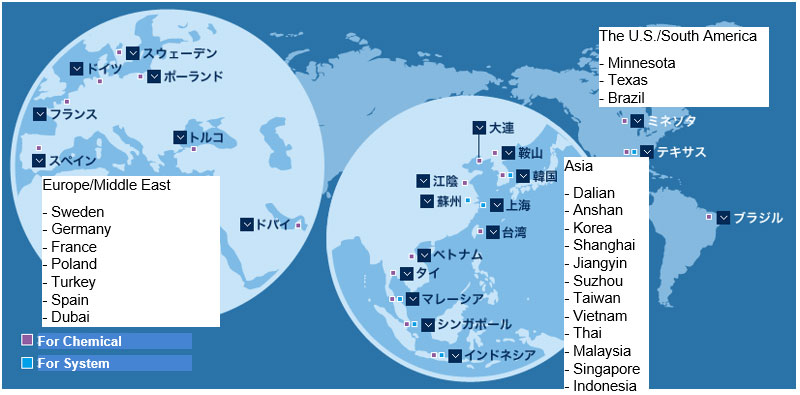

Kurita’s Global Network

Kurita will support your business with their wide network – 46 locations in Japan, 12 locations abroad and additional future support offices in alliance with trading companies.